Unugyada Gear Planetary ee saxda ah ee BAB

Kalsoonida

●Spiral gears comfiquration oo lagu ansixiyay saamiga hawlgelinta in ka badan laba jeer marshadaha caamka ah, waxa uu leeyahay xaalad orod aad u fudud, buuq yar, xoog wax soo saar oo sarreeya iyo nadiifin hoose.

● Gears waxay ka samaysan yihiin bir daawaha ah oo tayo sare leh, lagu dabaqay daawaynta engegnaanta dusha sare, lagu shiiday Furimaha Sare ee saxda ah, oo bixiya sifo adkeysiga u adkaysata iyo iska caabinta saamaynta.

| Qaabka NO | Marxalada | Saamiga | BAB042 | BAB060 | BAB060A | BAB090 | BAB90A | BAB115 | BAB142 | BAB180 | BAB220 | |

| (Mominal Output Torque Tzn) | Nm | 1 | 3 | 20 | 55 | - | 130 | - | 208 | 342 | 588 | 1140 |

| 4 | 19 | 50 | - | 140 | - | 290 | 542 | 1050 | 1700 | |||

| 5 | 22 | 60 | - | 16C | - | 330 | 650 | 1200 | 2000 | |||

| 6 | 20 | 55 | - | 150 | - | 310 | 600 | 1100 | 1900 | |||

| 7 | 19 | 50 | - | 14C | - | 300 | 550 | 1100 | 1800 | |||

| 8 | 17 | 45 | - | 120 | - | 260 | 500 | 1000 | 1600 | |||

| 9 | 14 | 40 | - | 100 | - | 230 | 450 | 900 | 1500 | |||

| 10 | 14 | 40 | - | 100 | - | 230 | 450 | 900 | 1500 | |||

| 2 | 15 | 20 | 55 | 55 | 130 | 130 | 208 | 342 | 588 | 1140 | ||

| 20 | 19 | 50 | 50 | 140 | 140 | 290 | 542 | 1050 | 1700 | |||

| 25 | 22 | 60 | 60 | 160 | 160 | 330 | 650 | 1200 | 2000 | |||

| 30 | 20 | 55 | 55 | 150 | 150 | 310 | 600 | 1100 | 1900 | |||

| 35 | 19 | 50 | 50 | 140 | 140 | 300 | 550 | 1100 | 1800 | |||

| 40 | 17 | 45 | 45 | 120 | 120 | 260 | 500 | 1000 | 1600 | |||

| 45 | 14 | 40 | 40 | 100 | 100 | 230 | 450 | 900 | 1500 | |||

| 50 | 22 | 60 | 60 | 160 | 160 | 330 | 650 | 1200 | 2000 | |||

| 60 | 20 | 55 | 55 | 150 | 150 | 310 | 600 | 1100 | 1900 | |||

| 70 | 19 | 50 | 50 | 140 | 140 | 300 | 550 | 1100 | 1800 | |||

| 80 | 17 | 45 | 45 | 120 | 120 | 260 | 500 | 1000 | 1600 | |||

| 90 | 14 | 40 | 40 | 10C | 10C | 230 | 450 | 900 | 1500 | |||

| 100 | 14 | 40 | 40 | 100 | 100 | 230 | 450 | 900 | 1500 | |||

| (Stop Emergency Torque Tznor | Nm | 1,2 | 3 ~ 100 | (3Times of Mominal Output Torque) | ||||||||

| (Xawaaraha Gelitaanka Magaca ah ee Nin) | rpm | 1,2 | 3 ~ 100 | 5,000 | 5,000 | 5,000 | 4000 | 4000 | 4000 | 3000 | 3000 | 2000 |

| (Xawaaraha Gelitaanka Magaca ah ee Nia) | rpm | 1,2 | 3 ~ 100 | 10,000 | 10,000 | 10,000 | 8000 | 8000 | 8000 | 6000 | 6000 | 4000 |

| (Micro Backlash PO) | arcmin | 1 | 3 ~ 10 | - | - | - | ≤1 | - | ≤1 | ≤1 | ≤1 | ≤1 |

| 2 | 15 ~ 100 | - | - | - | - | ≤3 | ≤3 | ≤3 | ≤3 | |||

| (Dib-u-dhaca P1 oo la dhimay) | arcmin | 1 | 3 ~ 10 | ≤3 | ≤3 | - | ≤3 | - | ≤3 | ≤3 | ≤3 | S3 |

| 2 | 15 ~ 100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | S5 | ≤5 | ||

| (Standard Backlash P2) | arcmin | 1 | 3 ~ 10 | ≤5 | ≤5 | ≤5 | - | ≤5 | ≤5 | ≤5 | ≤5 | |

| 2 | 15 ~ 100 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ||

| (Waxqabad) | % | 1 | S97% | |||||||||

| 2 | 15 ~ 100 | ≤94% | ||||||||||

| (Miisaan) | kg | 1 | 3 ~ 10 | 0.6 | 1.3 | - | 3.7 | - | 7.8 | 14.5 | 29 | 48 |

| 2 | 15 ~ 100 | 0.8 | 1.5 | 1.9 | 4.1 | 5.3 | 9 | 17.5 | 33 | 60 | ||

| (Xilku ku shaqaynayo) | ℃ | 1,2 | 3 ~ 100 | -10°℃~90℃ | ||||||||

| (Sifeyn) | 1.2 | Saliida loo yaqaan 'Syntheticlubrication oils' | ||||||||||

| (Degree ee Ilaalinta Gearbox) | 1,2 | IP65 | ||||||||||

| (Booska Koritaanka) | 1,2 | 3 ~ 100 | Dhammaan jihooyinka | |||||||||

| Sawaxan (n1=3000rpm i=10, wax rar ah malaha) | dB(A) | 1,2 | 3 ~ 100 | ≤56 | ≤58 | s60 | ≤60 | ≤63 | ≤63 | ≤65 | ≤67 | ≤70 |

Faahfaahinta Alaabta

Soo bandhigida badeecadayadii ugu dambeysay, wax dhimis la isku halayn karo oo la isku halayn karo! Loogu talagalay inay buuxiyaan shuruudo kala duwan oo ay keenaan waxqabad heersare ah, wax-yareeyayaashan waxay la yimaadaan astaamo iyo astaamo goyn.

Waxaa jira toddobo tilmaamood oo kala duwan oo laga xusho, oo ay ku jiraan 042, 060, 090, 115, 142, 180 iyo 220. Macaamiisha waxay si dabacsanaan ah u dooran karaan dhimisiyaha sida ugu fiican ugu habboon baahidooda. Haddi aad u baahato wareeg sare ama saami dhimis gaar ah, waanu ku daboolnay.

Isagoo ka hadlaya waxqabadka, dhimayayaashu waxay leeyihiin qulqulka wax soo saarka ee ugu sarreeya ee 2000Nm, isagoo hubinaya awood iyo hufnaan aad u wanaagsan. Intaa waxaa dheer, waxaa lagu heli karaa noocyo kala duwan oo ah saamiga dhimista hal-marxalad (laga bilaabo 3 ilaa 10), oo ku siinaya xakameyn weyn iyo ikhtiyaaro habeyn. Kuwa raadinaya heerar dhimis horumarsan, heerarkeena laba geesoodka ah waxaa ka mid ah 15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90 iyo 100.

Marka ay timaado in la isku halleyn karo, dhimayayaasheena runtii aad ayay u fiican yihiin. Habka dhimistoodu waxa ay qabataa nakhshad gear helical ah, iyo heerka isku xidhka iliggu waxa uu ka badan yahay laba jeer marka la barbar dhigo gearsyada caadiga ah. Tani waxay keenaysaa hawlgal siman, heerarka qaylada oo hooseeya iyo wax soo saarka sare. Intaa waxaa dheer, dhimayayaashayada waxaa loogu talagalay sifooyin nadiifin hooseeya oo hubinaya waxqabad aan toos ahayn oo qumman.

Si loo hubiyo adkeysiga iyo nolosha adeegga, gearsyada ku jira dhimayayaashayadu waxay ka samaysan yihiin walxo tayo sare leh. Gearsyadani waa kuwo kiis adag oo si taxadar leh loo farsameeyay iyadoo la isticmaalayo mishiinada qalabka saxda ah ee saxda ah, taas oo keenta qaybo adkaysi u leh, saamaynta u adkaysta iyo qaybo adag. Tani waxay hubisaa in dhimayayaashu ay u adkeysan karaan codsiyada iyo bay'ada ugu baahida badan.

Marka la soo koobo, dhimayayaashu waxay bixiyaan waxqabad aan la mid ahayn, isku halaynta iyo adkeysiga. Kala duwanaanshahooda kala duwan ee qeexitaannada, awoodaha qulqulka sarreeya iyo hoos u dhigista heerka sare ayaa ka dhigaya kuwo ku habboon warshadaha iyo codsiyada kala duwan. Annaga oo ay taageerayaan sida ay nooga go'an tahay tayada iyo qanacsanaanta macaamilka, waxaan ku kalsoonahay in wax-yareeyayaashayadu ay dhaafi doonaan waxyaabaha aad filayso oo ay ku siin doonaan waxqabad wanaagsan baahiyahaaga gaarka ah. Khibrad u yeelo awoodda iyo saxnaanta wax-dhimeyaashayada maanta!

Codsiga

1. Garoonka hawada sare

2. Warshadaha caafimaadka

3. Robots-warshadaha, Automation-ka Warshadaha, Qalabka mashiinka CNC ee wax soo saarka warshadaha baabuurta, daabacaadda, beeraha, warshadaha cuntada, injineernimada ilaalinta deegaanka, warshadaha saadka bakhaarka.

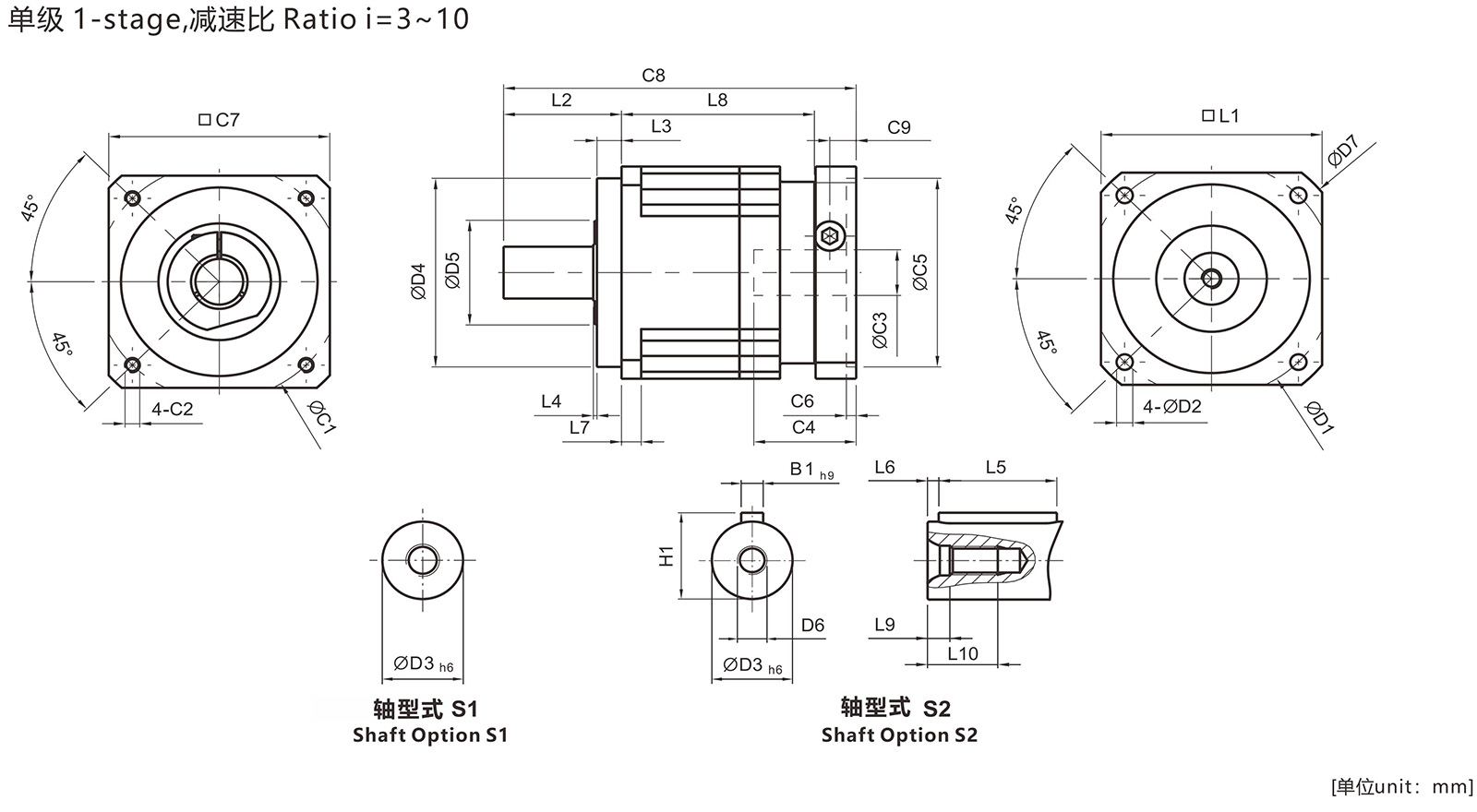

| Cabirka | BAB042 | BAB060 | BAB090 | BAB115 | BAB142 | BAB180 | BAB220 |

| D1 | 50 | 70 | 100 | 130 | 165 | 215 | 250 |

| D2 | 3.4 | 5.5 | 6.6 | 9 | 11 | 13 | 17 |

| D3h6 | 13 | 16 | 22 | 32 | 40 | 55 | 75 |

| D4g6 | 35 | 50 | 80 | 110 | 130 | 160 | 180 |

| D5 | 22 | 45 | 65 | 95 | 75 | 95 | 115 |

| D6 | M4x0.7P | M5×0.8P | M8×1.25P | M12×1.75P | M16×2P | M20x2.5P | M20x2.5P |

| D7 | 56 | 80 | 116 | 152 | 185 | 240 | 292 |

| L1 | 42 | 60 | 90 | 115 | 142 | 180 | 220 |

| L2 | 26 | 37 | 48 | 65 | 97 | 105 | 138 |

| L3 | 5.5 | 7 | 10 | 12 | 15 | 20 | 30 |

| L4 | 1 | 1.5 | 1.5 | 2 | 3 | 3 | 3 |

| L5 | 16 | 25 | 32 | 40 | 65 | 70 | 90 |

| L6 | 2 | 2 | 3 | 5 | 5 | 6 | 7 |

| L7 | 4 | 6 | 8 | 10 | 12 | 15 | 20 |

| L8 | 31 | 61 | 78.5 | 102 | 104 | 154 | 163.5 |

| L9 | 4.5 | 4.8 | 7.2 | 10 | 12 | 15 | 15 |

| L10 | 10 | 12.5 | 19 | 28 | 36 | 43 | 42 |

| C11 | 46 | 70 | 100 | 130 | 165 | 215 | 235 |

| C21 | M4x0.7Px10 | M5x0.8Px12 | M6x1Px12 | M8X1.25Px25 | M10x1·5Px25 | M12x1.75Px28 | M12x1.75Px28 |

| C31 G7 | ≤11/≤122 | ≤14/≤16² | ≤19/≤24 | ≤32 | ≤38 | ≤48 | ≤55 |

| C41 | 25 | 34 | 40 | 50 | 60 | 85 | 116 |

| C51 G7 | 30 | 50 | 80 | 110 | 130 | 180 | 200 |

| C61 | 3.5 | 4 | 6 | 5 | 6 | 6 | 6 |

| C71 | 42 | 60 | 90 | 115 | 142 | 190 | 220 |

| C81 | 86.5 | 117 | 143.5 | 186.5 | 239 | 288 | 364.5 |

| C91 | 8.75 | 13.5 | 10.75 | 13 | 15 | 20.75 | 53 |

| B1h9 | 5 | 5 | 6 | 10 | 12 | 16 | 20 |

| H1 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79.5 |

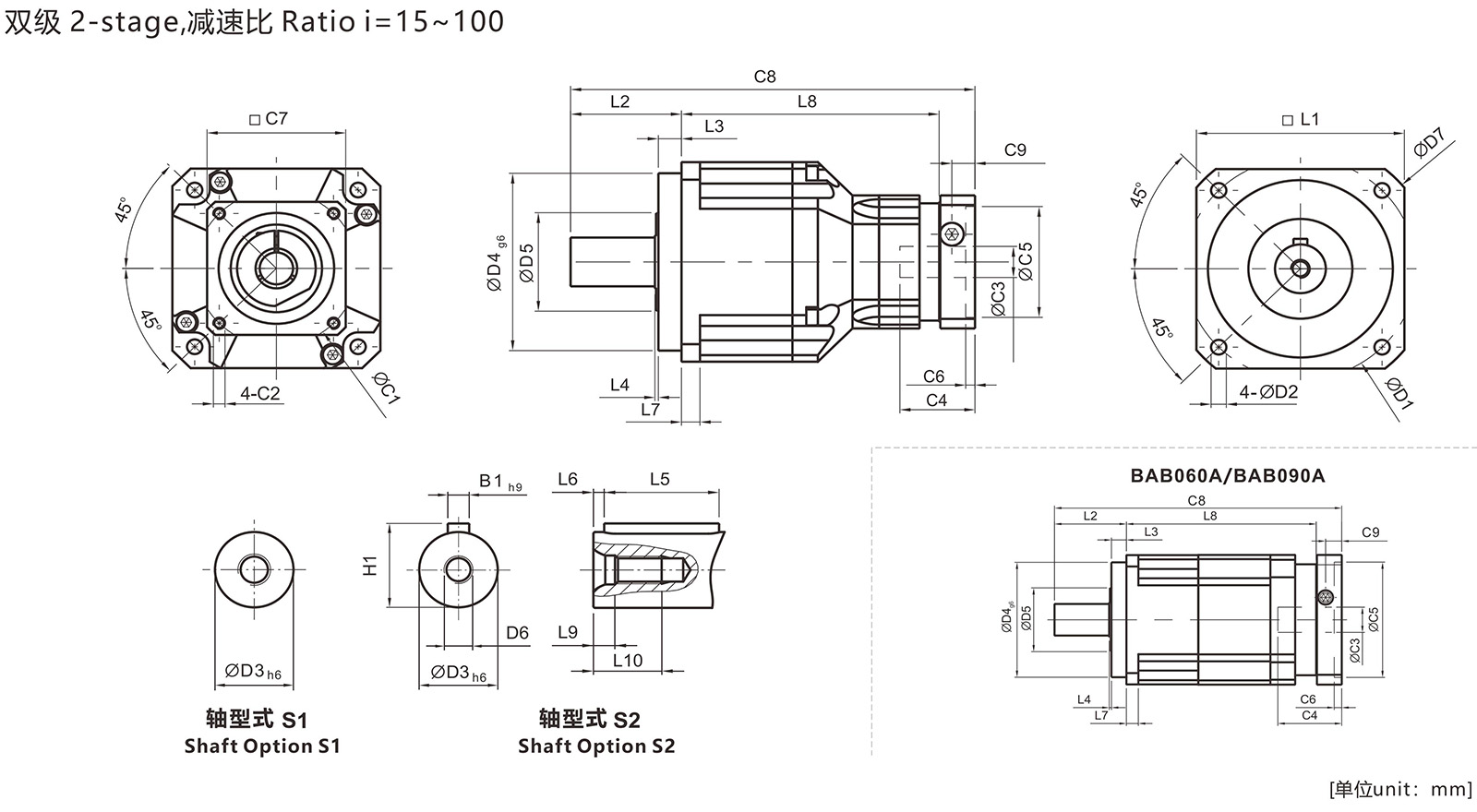

| Cabirka | BAB042 | BAB060 | BAB060A | BAB090 | BAB090A | BAB115 | BAB142 | BAB180 | BAB220 | |

| D1 | 50 | 70 | 100 | 130 | 165 | 215 | 250 | |||

| D2 | 3.4 | 5.5 | 6.6 | 9 | 11 | 13 | 17 | |||

| D3h6 | 13 | 16 | 22 | 32 | 40 | 55 | 75 | |||

| D4g6 | 35 | 50 | 80 | 110 | 130 | 160 | 180 | |||

| D5 | 22 | 45 | 65 | 95 | 75 | 95 | 115 | |||

| D6 | M4x0.7P | M5×0.8P | M8×1.25P | M12×1.75P | M16×2P | M20x2.5P | M20x2.5P | |||

| D7 | 56 | 80 | 116 | 152 | 185 | 240 | 292 | |||

| L1 | 42 | 60 | 90 | 115 | 142 | 180 | 220 | |||

| L2 | 26 | 37 | 48 | 65 | 97 | 105 | 138 | |||

| L3 | 5.5 | 7 | 10 | 12 | 15 | 20 | 30 | |||

| L4 | 1 | 1.5 | 1.5 | 2 | 3 | 3 | 3 | |||

| L5 | 16 | 25 | 32 | 40 | 65 | 70 | 90 | |||

| L6 | 2 | 2 | 3 | 5 | 5 | 6 | 7 | |||

| L7 | 4 | 6 | 8 | 10 | 12 | 15 | 20 | |||

| L8 | 58.5 | 72 | 98 | 111.5 | 126.5 | 143.5 | 176 | 209.5 | 248 | |

| L9 | 4.5 | 4.8 | 7.2 | 10 | 12 | 15 | 15 | |||

| L10 | 10 | 12.5 | 19 | 28 | 36 | 42 | 42 | |||

| C11 | 46 | 46 | 70 | 70 | 100 | 100 | 130 | 165 | 215 | |

| C21 | M4x0.7Px10 | M4x0.7Px10 | M5x0.8Px12 | M5x0.8Px12 | M6x1Px12 | M6x1Px12 | M8x1.25Px25 | M10x1.5Px28 | M12x1.75Px28 | |

| C31 G7 | ≤11/≤12 | ≤11/≤12 | ≤14/≤16 | ≤14/15.875/≤16 | ≤19/≤24 | ≤19/≤24 | ≤32 | ≤38 | ≤48 | |

| C41 | 25 | 25 | 34 | 34 | 40 | 40 | 50 | 60 | 85 | |

| C51 G7 | 30 | 30 | 50 | 50 | 80 | 80 | 110 | 130 | 180 | |

| C61 | 3.5 | 3.5 | 4 | 6 | 4 | 4 | 5 | 6 | 6 | |

| C71 | 42 | 42 | 60 | 60 | 90 | 90 | 115 | 142 | 190 | |

| C81 | 114 | 138.5 | 154 | 178.5 | 191.5 | 225.5 | 292.5 | 337 | 415 | |

| C91 | 8.75 | 8.75 | 13.5 | 13.5 | 10.75 | 10.75 | 13 | 15 | 20.75 | |

| B1h9 | 5 | 5 | 6 | 10 | 12 | 16 | 20 | |||

| H1 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79.5 | |||